Contact stress analysis of a spur gear using Lewis and Hertz theory

DOI:

https://doi.org/10.23917/arstech.v2i2.165Keywords:

Ansys, Finite Element Method, Safety factor, Contact stress, Finite element analysisAbstract

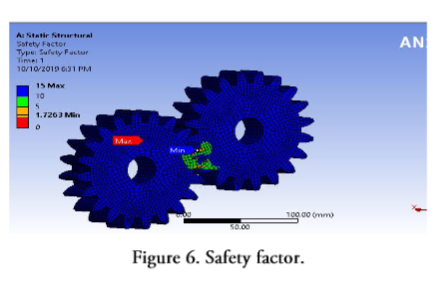

The rapid development of the automobile and aircraft industries has made applying gear technology necessary. Gears offer the benefits of efficiency, reliability, simplicity and a higher speed ratio with power transmission. However, they cannot transmit power over a long period, are more expensive when compared to belts and chain drives and requires continuous lubrication. They are used for transmitting high load in gear tools. The gear teeth fail when subjected to a high load beyond a certain limit. A deciding factor in gear design is the amount of stress developed on the contact surface of the mating gears. This paper deals with contact stress analysis of spur gear. The theoretical analysis presented in this paper aims to analyse rolling bearing contacts based on the principles of the Hertz and Lewis equations. A 3D domain-based finite element method was used to calculate the stresses between the contact surfaces of the structure. Contact analysis was performed using ANSYS Workbench software to figure out the deformation and optimum stress developed on the teeth of the gear. The simulation results indicated that the stress distribution on the gear contact surface has a maximum value of 144.82 MPa, while the deformation is at a maximum value of 0.01676 mm. The safety factor indicates the maximum level of 15, indicating the safety of the design.

Downloads

References

T.S. Rani, and T. Dada Khalandar, "Spur gear," International Journal of Computational Engineering Research, vol. 3, no. 11, pp. 7-12, 2013.

V. Wable, and D.M. Mate, "An investigative study of spur gear failure by FEA and photoelastic method", International Engineering Research Journal, pp. 746-751, 2016.

H.P. Rahate, and R.A. Marne, "Contact Stress analysis of composite spur gear using photo-stress method and finite element analysis", International Research Journal of Engineering and Technology (IRJET), vol. 3, no. 7, pp. 540-545, 2016.

B. Desai, and M.A. Mohite, "Analysis of fatigue crack growth rate and service life of spur gear", International Engineering Research Journal, pp. 1685-1689, 2006.

Sunil, and G. Janiyani, Machine design, Rajkot: Department of Mechanical Engineering Darshan Institute of Engineering & Technology, 2017.

V. S. Prasad, S. A. Hussain, V. Pandurangadu, and K. Palanikumar, "Modeling and Analysis of spur gear for sugarcane juice machine under static load condition by using FEA", International Journal of Modern Engineering Research (IJMER), vol. 2, no. 4, pp. 2862-2866, 2012.

P.B. Pawar, and A.A. Utpat, "Development of Aluminium based silicon carbide particulate metal matrix composite for spur gear", The 3rd International Conference on Materials Processing and Characterisation (ICMPC 2014), India, 2014.

A. Muhammad, M.A.H. Ali, and I.H. Shanono, "Finite Element Analysis of a connecting rod in ANSYS: An overview", The 11th Malaysian Technical Universities Conference on Engineering and Technology (MUCET), Malaysia, 2019.

Klaus-Jurgen, Bathe, Finite Element Procedures (USA), USA: Prentice Hall, Pearson Education, Inc, 2014.

A. Muhammad, and I.H. Shanono, "Strength analysis and structural optimisation of an l-shaped bracket", Nigerian Journal of Technological Research, vol. 13, pp. 14-19, 2018.

Y. Nakasone, S. Yoshimoto, and T. Stolarski, Engineering Analysis with ANSYS Software, UK: MPG Books Ltd., Bodmin, Cornwall, 2006.

D. Neelima, V. Mahesh, and N. Selvaraj, "Mechanical characterisation of Aluminium silicon carbide composite", International Journal of Applied Engineering Research, vol. 1, no. 4, pp. 126-131, 2011.

S. Hwang, J. Lee, D. Lee, S. Hana, and K. Lee, "Contact stress analysis for a pair of mating gears", Mathematical and Computer Modelling, vol. 57, p. 40–49., 2013. https://doi.org/10.1016/j.mcm.2011.06.055.

V. Nikolic-Stanojevic, and I. Cvejic, "The Analysis of contact stress on meshed teeth's flanks along the path of contact for a tooth pair", Mechanics, Automatic Control and Robotics, vol. 3, pp. 1055-1066, 2003.

K. Markovic, and M. Franulovic, "Contact stresses in gear teeth due to tip relief profile modification", Engineering review, vol. 31, no. 1, pp. 19-26, 2011. https://hrcak.srce.hr/70383

S.K. Tiwari, and U.K. Joshi, "Stress analysis of mating involute spur gear teeth", International Journal of Engineering Research and Technology, vol. 1, no. 9, pp. 1-12, 2012.

K. Mao, "new approach for polyamide composite gear design", Wear, vol. 262, pp. 432-441, 2007.

B. Gupta, A. Choubey, and G.V. Varde, "Contact stress analysis of spur gear", International Journal of Engineering Research and Technology, vol. 1, no. 4, pp. 1-7, 2012.

S.A. Quadri, and D.R. Dolas, "Contact stress analysis of involute spur gear under static loading", International Journal of Scientific Research Engineering & Technology (IJSRET), vol. 4, no. 5, pp. 593-596, 2015.

A. Muhammad, and I.H. Shanono, "Static analysis and optimisation of a connecting rod", International Journal of Engineering Technology and Sciences , vol. 6, pp. 24-40, 2019. http://dx.doi.org/10.15282/ijets.6.1.2019.1003

A. Muhammad, and I.H. Shanono, "Transient analysis and optimisation of a knuckle joint", KINETIK, vol. 4, no. 2, pp. 179-186, 2019. https://doi.org/10.22219/kinetik.v4i2.767

A. Muhammad, M.A.H. Ali, and I.H. Shanono, "Finite element analysis of a connecting rod in ANSYS: An overview", IOP Conference Series: Materials Science and Engineering , vol. 736, No. 2, p. 022119. 2020. https://doi.org/10.1088/1757-899X/736/2/022119

A. Muhammad, and I.H. Shanono, "Finite element analysis of the heat transfer in a piston", Journal of Modern Manufacturing Systems and Technology, vol. 4, no. 1, pp. 45-51, 2020. https://doi.org/10.15282/jmmst.v4i1.3722

Downloads

Published

How to Cite

Issue

Section

Categories

License

Copyright (c) 2022 Aisha Muhammad, Ibrahim Haruna Shanono

This work is licensed under a Creative Commons Attribution 4.0 International License.