The effect of internal pressure and thickness on the creep strain of the superheater pipes

DOI:

https://doi.org/10.23917/arstech.v1i1.21Keywords:

Pipe thickness, Creep strain Alloy 617, Superheater pipe, Internal pressure, AbaqusAbstract

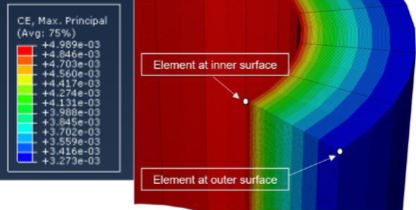

Superheater pipes in turbines commonly are used to produce superheated steam. Internal pressure is critical for steam superheater elements. The pipes in such applications are vulnerable to temperature environments, which can bring the component to enter the creep regime, creep deformation, or even creep fracture. In general, most of the failures in boilers are caused by creep. Creep-resistant materials used in facilities operated at high temperatures must, therefore, be able to withstand the highest possible temperature loads. This study aims to investigate the creep behaviour of a 617 alloys steel steam pipe, which operated within 100,000 hours. The temperature of steam was set at 700?C, and the pressure in the pipe was 35 MPa. Abaqus software based on the finite element method was used in the study. The effect of internal pressure and pipe thickness on the creep strains was observed. The variation of the internal pressure was 35, 37.5, 40, 42.5, and 45 MPa. Whereas, the thickness variations were 30, 35, 40, 45, and 50 mm. The simulation results revealed that an increase in the internal pressure and the decrease of the pipe thickness increase the creep strain. This study can be used to predict the possibility of creep damaged for the superheater pipes operated at high temperatures, which have different thicknesses.

Downloads

Downloads

Published

How to Cite

Issue

Section

Categories

License

Copyright (c) 2020 Tri Widodo Besar Riyadi, Sopyan Sahid Fatuloh

This work is licensed under a Creative Commons Attribution 4.0 International License.