The effectivity of used-oil as quenching medium of 42-CrMo4 steel for automotive materials

DOI:

https://doi.org/10.23917/arstech.v1i1.11Keywords:

Hardening-quenching , Hardness, Martensite, 42CrMo4 steel, Used-oilAbstract

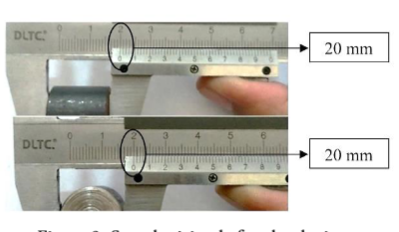

The research aims to investigate the effect of the cooling medium on the hardness characteristic and microstructure of the 42CrMo4 steel due to hardening treatment at a temperature of 830°C and holding time of 30 minutes. Various oil such as SAE-10W40, SAE-20W50, SAE-40, and used oil was used in the cooling medium. The changes in product size, hardness, and microstructure have been carefully assessed. The results indicated that the viscosity of the coolant medium strongly influenced the cooling rate of the cooling medium, hardness, and microstructure. SAE-10W40 oil and SAE-20W50 oil only needed 2 hours to return within room temperatures before quenching, whereas SAE-40 oil and used oil took 3 hours. The sample size did not change after hardening-quenching. However, there was a residual carbon layer on the sample surfaces. Quenching caused the changes of microstructure from pearlite and ferrite to ultrafine double phase, consisting of martensite and austenite, which were unable to transform during rapid cooling. The highest hardness value was achieved by the treated product, which was quenched in SAE-10W40, which had 54.59 HRC. The high hardness was attributed to the content of 95% martensite. However, used-oil caused in similar hardness as SAE-20W50.

Downloads

Downloads

Published

How to Cite

Issue

Section

Categories

License

Copyright (c) 2020 Hariningsih Hariningsih, Sumpena Sumpena, Heribertus Sukarjo

This work is licensed under a Creative Commons Attribution 4.0 International License.