DESIGN AND SAFETY FACTOR SIMULATION OF AN AUTOMATED FEEDER FOR BLANKING MACHINES

DOI:

https://doi.org/10.23917/mesin.v26i2.6977Keywords:

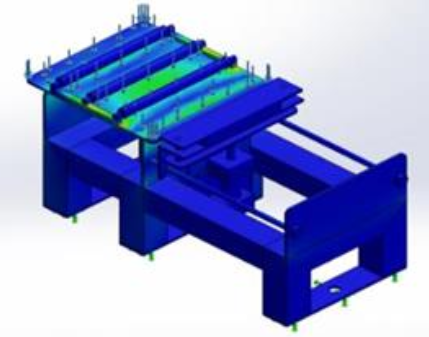

simulation, feeder, blanking, safety factor, designAbstract

The displacement of the stainless-steel plate to the printing work area is still managed manually by the

operator. Additionally, there is no clear benchmark to determine whether the plate is in the correct position and

aligned according to the printed pattern. Thus, the print results are frequently less than perfect and require a long

process. To address these conditions, an additional feeder is required with an automatic system that can operate

in conjunction with the blanking machine, simplifying the operator's work and enhancing the blanking process

efficiency. The objectives of this research are to determine the design of the feeder machine design by the needs

and specifications of the machine, to discover the value of the safety factor of the Feeder machine design, and to

reveal the movement system of the Feeder machine design using SolidWork 2019. This final project was carried

out in June 2023 at Politeknik Industri Logam Morowali (PILM) in Labota Village, Bahodopi District, Morowali

Regency, Central Sulawesi Province. The results show that: Researchers can make a design with the provisions

of a length of 550 mm and a width of 250 mm, while the known safety factor value for both areas is declared safe

since it has Factor of Safety (FOS) value of 1 and the design movement system displayed on the animation system

in SolidWork 2019 software.

Downloads

Downloads

Submitted

Accepted

Published

Issue

Section

License

Copyright (c) 2025 Hendi Lilih Wijayanto, Zulfianti, Yusdianto, Hairun Apriadi Ramadhan S, Usman

This work is licensed under a Creative Commons Attribution 4.0 International License.