OPTIMIZING PROCESS PARAMETERS FOR FILAMENT 3D PRINTING USING THERMOPLASTIC POLYURETHANE (TPU) WITH RESPONSE SURFACE METHODOLOGY (RSM)

DOI:

https://doi.org/10.23917/mesin.v26i2.4771Keywords:

3D printing, filament TPU, response surface methodology (RSM)Abstract

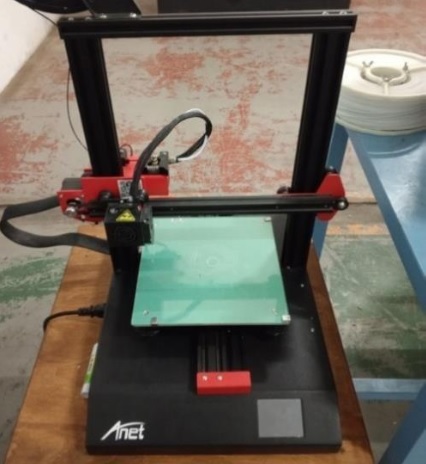

3D Printing utilizes the fabrication process of Fused Deposition Modeling (FDM), which is an Additive Manufacturing (AM) technology that builds objects layer by layer (Pristiansyah et al., 2019). The use of 3D Printing technology has rapidly increased in recent years, significantly contributing to the quality and cost efficiency of prototype production. TPU (Thermoplastic Polyurethane) filament is often used because it produces heavier, harder, and more durable products. Optimizing the 3D printing process is crucial to achieving optimal results, one of which is through the Response Surface Methodology (RSM) method. In this study, RSM was used with 2 factors to find the best response in tensile strength and material hardness of TPU. The experimental results showed that the optimal parameters for tensile strength are a temperature of around 190°C and a print speed of 45mm/m, resulting in a tensile strength of 2.34 kgf/mm². Meanwhile, for maximum hardness, the optimal parameters are a temperature of 214.15°C and a print speed of 45mm/m, with a hardness value of 72.67 HRR. Thus, the RSM method can be an effective approach in improving the 3D Printing results on TPU material.

Downloads

Downloads

Submitted

Accepted

Published

Versions

- 2025-07-31 (2)

- 2025-07-31 (1)

Issue

Section

License

Copyright (c) 2025 Umi Khulsum Salbiah, Apang Djafar Shieddique, Rohman Rohman

This work is licensed under a Creative Commons Attribution 4.0 International License.