ANALYSIS OF CUTTING FLUID ON MASS LOSS OF CARBIDE INSERT IN THE MILLING PROCESS

DOI:

https://doi.org/10.23917/mesin.v25i1.2896Keywords:

Milling, Coolant, Tool Wear, Carbide InsertAbstract

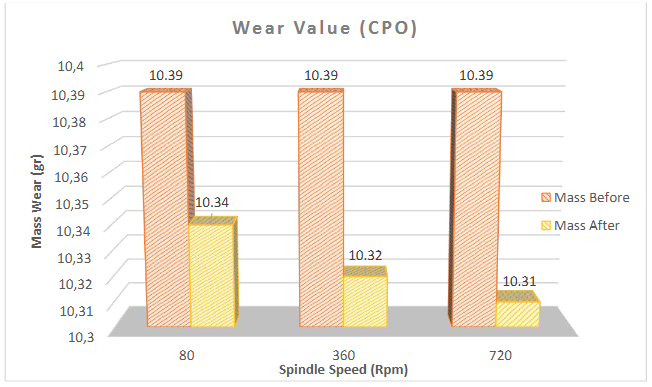

The Machining process is manufacturing in the world industry that is widely used. The coolant in the machining process functions to lower the temperature and lubricate and clean the gram in the cutting process. The application of coolant in the cutting process is to maintain the quality of the workpiece during the cutting process and also serves to improve tool life so that the tool does not wear out easily. This study aims to determine the effect of a chemical-based coolant based on dromus oil and vegetable CPO on tool wear in the face milling process and to determine whether or not the liquid is effective in reducing and slowing down tool wear. In this research, the face milling process used a grey cast iron specimen as the workpiece specimen used and also used a carbide insert chisel cutting tool with the TPKN 22 VC2 type. The research was carried out by varying the engine speed and also the coolant variation, the engine speed variations used were 80, 360 and 720 Rpm. In the process of administering coolant using the method, it is sprayed directly onto the workpiece area which is cut continuously, in the milling process with a response variable that can be in the form of data or tool wear values that have been observed and tested using a microscope test tool, using the weight (mass) method to see the wear value. This research aims to see how effective the use of vegetable- based coolant (CPO) during experiments as a coolant in the machining process aims to ensure that the final value of tool insert wear must be smaller with (CPO) compared to chemical coolant (dromus).

Downloads

Downloads

Submitted

Accepted

Published

Versions

- 2024-01-31 (3)

- 2025-01-12 (2)

- 2024-01-30 (1)

Issue

Section

License

Copyright (c) 2024 Arya Rudi Nasution, Affandi Affandi, Khairul Umurani, Rahmatullah Rahmatullah, Muhammad Refan

This work is licensed under a Creative Commons Attribution 4.0 International License.