Development of Casting Product Using Reverse Engineering Technology: A Case Study

DOI:

https://doi.org/10.23917/jiti.v23i1.4200Abstract

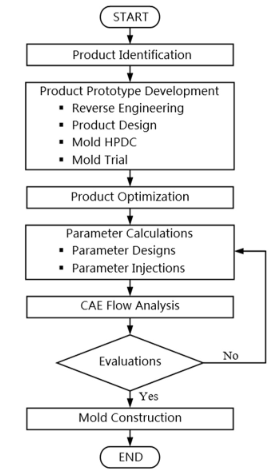

Abstract. One solution to increase domestic industry competitiveness and performance is mastering reverse engineering (RE) technology. Through mastery of this technology, the use of domestic components will increase. However, this is still an obstacle due to a weak understanding of RE technology and the availability of RE facilities. This article will examine the RE process of a casting product and optimize the product manufacturing process through simulation with casting software for the High-Pressure Die Casting (HPDC) process with a case study of a top body converter product. This research begins with product identification, development, and optimization. The next step is to determine the design and injection parameters to be simulated in the Inspire casting software and then design the HPDC mold. Through RE technology, this research has produced an optimal top body converter product with a weight 36% lighter than the initial weight, and an HPDC mold design for the optimal product has been produced.

Downloads

Submitted

Accepted

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Jurnal Ilmiah Teknik Industri

This work is licensed under a Creative Commons Attribution 4.0 International License.