Design of Work Facility Improvements with a Macroergonomic Analysis and Design (MEAD) Approach in SMEs Andri Tofu

DOI:

https://doi.org/10.23917/jiti.v23i1.3017Keywords:

MEAD, MSDs, REBA, Work SystemAbstract

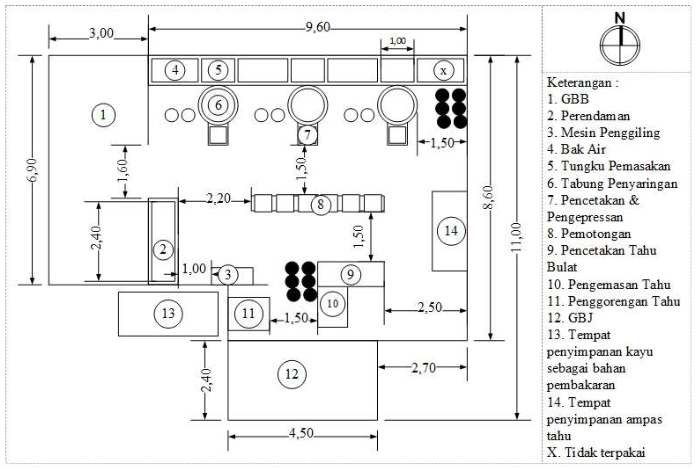

Small and Medium Enterprises Andri tofu is an industry engaged in food production which is located in Ngrampal District, Sragen. In the production process there is a non-optimal working system, where the process of setting up the mold tool takes more than 1 minute and the pressing process uses a load of more than 17 kg in the form of using a 20 liter bucket full of water. The purpose of this study is to identify the factors that influence the work system, measure complaints and posture, and design work facility improvement designs. The method used is in the form of Macroergonomic Analysis and Design to design work systems and facilities based on the location of the highest deviation. The results of the study found that there were dominant body complaints on the right hand by 5.18% and mild complaints on the thighs by 1.41%. Improvements to the design of the tool have an adjustable height of 140-170 cm, a width of 72 cm, a height of 57 cm for the feet of the tool, and the pressing uses a gear system with a rack gear of 70 cm and diameter a spin gear of 6 cm which is driven using a rotary press stirrer.

Downloads

Submitted

Accepted

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Jurnal Ilmiah Teknik Industri

This work is licensed under a Creative Commons Attribution 4.0 International License.