Production Floor Relayout to Optimize Material Handling Distance at PT. Sidoagung Farm Magelang

-

DOI:

https://doi.org/10.23917/jiti.v23i1.3332Keywords:

Key Words : Group Technology, Rank Order Clustering, Blockplan, RectilinearAbstract

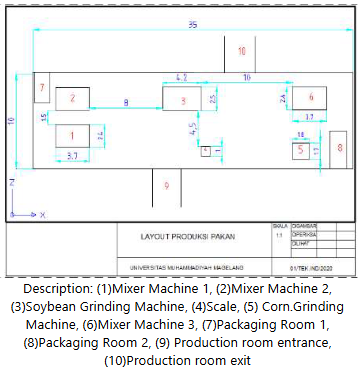

PT. Sidoagung Farm Magelang is one of the industries engaged in animal feed. The problem in this company is the arrangement of machines per department on an irregular production line, so that the interrelated production processes are quite far apart. Machines that have the same function and are far apart include: corn grinding machine and soybean grinder 9 meters apart, mixer machine 1, mixer machine 2 and mixer machine 3 each 1.5 meters and 18 meters apart, packaging 1 and packaging 2 is 27.4 meters away. In order to overcome these problems, this study proposes a method to optimize distance using a Group Technology approach, namely the Rank Order Clustering (ROC) method for grouping machines with similar parts. The design of the proposed layout uses Blockplan Software and the calculation of the distance with the rectilinear formula. The results of this study resulted in 3 grouping machines. Group 1 grinding machines are 1 meter apart, group 2 mixer machines are 1 meter apart each, group 3 packaging machines are 1.5 meters apart. The total displacement of the material handling distance using the rectilinear formula in the initial layout is 191 meters, while for the displacement of the material handling distance, the proposed layout is 117.5 meters. With the comparison of the initial and proposed layout distance is 73.5 meters so that the proposed layout optimizes the distance between machines by 62%.

Downloads

Submitted

Accepted

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Jurnal Ilmiah Teknik Industri

This work is licensed under a Creative Commons Attribution 4.0 International License.