THE EFFECT OF USING DUST AS A BENTONITE SUBSTITUTION ON THE CHARACTERISTICS OF RECYCLED GREENSAND MOLDS

Keywords:

using dust, metal casting, molding sand, greensand, green compression strengthAbstract

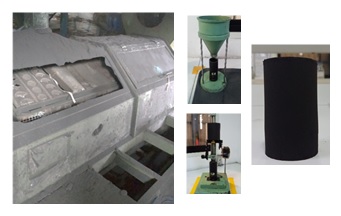

The metal casting industry faces global challenges in managing greensand dust waste containing silica and clay from bentonite and silica sand, which has the potential to cause environmental and health impacts. Therefore, this study analyzes the effect of greensand dust utilization on the characteristics of greensand molds made from return sand. Additionally, this study aimed to ascertain the ideal percentage of dust required to attain the maximum green compression strength (GCS) value. This study examined dust usage variations of 0%, 15%, 30%, and 45% relative to the weight of bentonite. When calculated based on the weight of sand, these proportions translate to 0%, 0.09%, 0.18%, and 0.27%. The sand underwent several tests, including assessments for compactibility, moisture, permeability, grain fineness number (GFN), green compression strength (GCS), dry compression strength (DCS), wet tensile strength (WTS), active clay, volatile combustible material (VCM), and loss on ignition (LOI). The application of dust from greensand molds in the metal casting sector suggests that this dust can effectively replace bentonite. The ideal formulation for the molding sand includes 100% return sand, 0.42% bentonite, 0.18% dust, and 2.9% water. Specifically, the most efficient binder combination consists of 70% bentonite and 30% dust. This particular mixture achieves the highest GCS of 13.4 N/cm². A greater GCS value signifies that the molding sand possesses an improved ability to withstand the pressure from the molten metal during the pouring process.

Downloads

Downloads

Submitted

Accepted

Published

Issue

Section

License

Copyright (c) 2026 Hariningsih Hariningsih, Tasha Rizka

This work is licensed under a Creative Commons Attribution 4.0 International License.