STUDY OF INNER AND OUTER POCKET CHARACTERISTICS USING AREA ROUGHING METHOD

DOI:

https://doi.org/10.23917/mesin.v25i2.4628Keywords:

pocket milling, area roughing, depth cut, step over percentAbstract

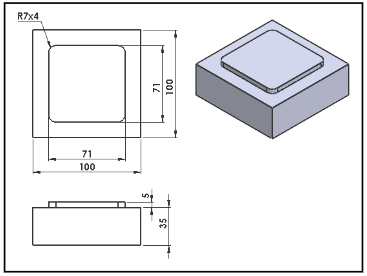

Pocket milling is one of the CNC milling processes. This research aims to analyze the characteristics of pocket milling using Area Roughing on surface roughness and machining time. The method applied is experimental research on the Area Roughing method for working on inner and outer pockets. Research variables include depth cut 0.5, 1, 1.5, and 2 mm, stepover percent 40, 50, and 60%. The test is in the form of surface roughness value, while the analysis of the machining process is the time during the milling process. The workpiece material is 2024 aluminum and a flat endmill tool with a diameter of 12 mm. The expected result is the parameter that has the most optimal value for the processing time and surface roughness value. So it can be a guide for milling processes, especially those that use Area Roughing. The machining results show that the faster machining time results from larger settings for depth cut and stepover percent. Average machining time increase of 28%. Meanwhile, the surface roughness value will increase as the depth cut and stepover settings increase, namely 17.65% for the outer pocket and 18.61% for the inner pocket. The surface roughness value of the ordering results ranges from 2.4-4.8 µm.

Downloads

Downloads

Submitted

Accepted

Published

Versions

- 2024-07-31 (2)

- 2024-07-31 (1)

Issue

Section

License

Copyright (c) 2024 Edy Suryono, Y. Yulianto Kristiawan, Emanuel Budi Raharjo, Jonas Andika Siburian, Jodi Muhammad Fajar

This work is licensed under a Creative Commons Attribution 4.0 International License.