CLAMPING DIES DESIGN TO MINIMIZE AUTOMOTIVE COMPONENT DIES SETUP TIME AT PT GANDING TOOLSINDO

DOI:

https://doi.org/10.23917/mesin.v25i2.3012Keywords:

dies clamping dies , design, MTM, setup diesAbstract

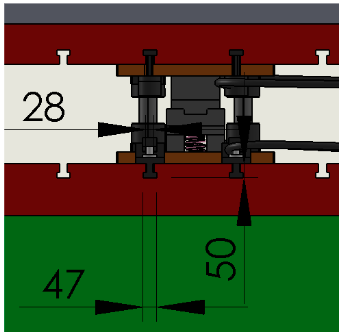

PT Ganding Toolsindo was faced with the problem of high automotive component die setup times. The main cause of the high setup time is the process of tightening and releasing the bolts which is done manually. The aim of this research is to design a tool for clamping dies which functions to help speed up the bolt installation process, so that the setup time for automotive component dies is reduced. The method used in this research is field observation followed by the die clamping design process. Design planning begins by drawing the object using CAD software based on the results of load calculations and determining the dimensions of the dies themselves and the press machine as well as selecting the dies material. Furthermore, proof was carried out that this die clamping design could reduce dies setup time using movement analysis with a pre-determined time study Measurement Time Method (MTM) method, where the results showed a time saving of 92.4%.

Downloads

Downloads

Submitted

Accepted

Published

Versions

- 2024-07-31 (2)

- 2024-07-31 (1)

Issue

Section

License

Copyright (c) 2024 Sanurya Putri Purbaningrum, Indah Kurnia Mahasih Lianny, Edwin Sahrial Solih, Abdul Wahid Arohman, Bayu Satiman

This work is licensed under a Creative Commons Attribution 4.0 International License.